Curved or bent laminated glass

Curved or bent laminated glass is produced by permanently bonding too pieces of glass together with an interlayer or resin. Several types of film and glass may be applied in the process, to obtain different characteristics for the structures - according to the purpose of use.

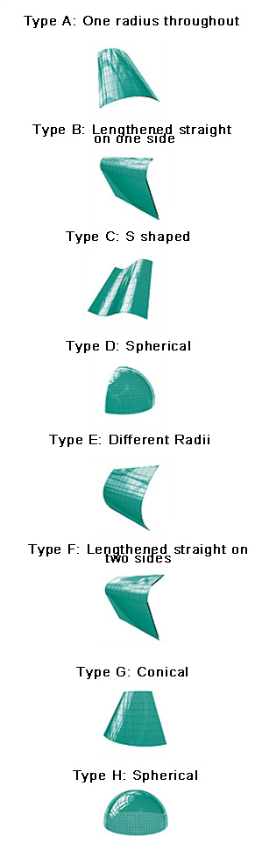

Curved or bent laminated glass protects from personal injuries; in the lowest protection class from falling, and in the sturdiest class from bullets and pressure waves caused by explosions. In addition to the protection class, the size of glass, its bending angle and bending form affect the durability classification of glass. When the number of glass layers and films is increased, it is possible to build multi-layer glasses for various, demanding protection needs.

Interesting decorative but also functional possibilities arise from the variety of the available Interlayers`. In other words, products in which can be integrated in the plastic intermediate layer can therefore add an aesthetic aspect to the existent safety.

Curved tempered glass

The strength of tempered safety glass is based on the thermal treatment applied to the glass. The glass is heated to the temperature of approx. 650°C, when the glass becomes softer and tensions disappear. After that, the glass is cooled rapidly, when a constant compression stress remains on the surface of the glass, and a constant tensile stress in the middle part.

The strength of tempered glass is increased to approx. fivefold compared with untreated glass. The safety characteristics of tempered glass are emphasized also when the glass is broken, when it breaks into small fragments without causing bigger wounds when getting into skin contact.

The most important stage in the manufacturing of tempered safety glass is to make the optical qualities of the glass to remain unaltered. In the bending & tempering process the glass is being heated in two phases partly by means of circulating air, when the optics of the glass remain as ideal. The importance of the optical constancy is emphasized in large reflecting glass surfaces.

The design is often based on the need for bigger curved glass surfaces, concealed fixing and structures applied without casement and framework. Thanks to better durability, safety and bigger glass sizes, tempered curved glass is a reasonable alternative for these challenging structures.